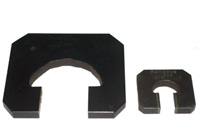

A Ring Gauge is a precision cylindrical measuring tool used to inspect and verify the external diameter of shafts, pins, and turned components. Manufactured to tight tolerances and calibrated to international standards, ring gauges ensure consistent dimensional accuracy in production and quality control environments.

Key Features:

✅ High-Grade Tool Steel or Carbide:

Made from hardened alloy steel (commonly 58–62 HRC) or solid carbide for superior wear resistance and long-lasting accuracy, even in high-volume inspection.

✅ Precision Ground Bore:

The internal diameter is ground and lapped to exact tolerances, delivering precise Go/No-Go verification of external dimensions.

✅ Go/No-Go Design:

Available in Go/No-Go pairs—Go gauges confirm minimum material condition, while No-Go gauges confirm maximum allowable diameter.

✅ Clear Identification:

Laser-engraved markings specify nominal size, tolerance class, gauge type (Go/No-Go), and serial numbers for traceability and compliance.

✅ Optional Handles:

Supplied with knurled or insulated handles to facilitate easy handling and avoid heat transfer that can affect measurements.

✅ Calibration Certification:

Delivered with calibration certificates traceable to national or international standards (ISO, DIN, ASME), supporting quality management systems.

Applications:

- Checking external diameters of shafts, pins, studs, and turned components

- Acceptance inspection in automotive, aerospace, bearing, and precision engineering industries

- In-process control to monitor tool wear and dimensional drift

- Calibration and reference standards in metrology labs

Benefits:

🔹 Consistent Dimensional Control:

Ensures components conform to specified tolerances, reducing scrap and rework.

🔹 Fast Verification:

Quick Go/No-Go checks save inspection time and improve throughput.

🔹 Reliable Accuracy:

Hardened and stabilized materials maintain dimensional stability over thousands of cycles.

🔹 Traceable Compliance:

Supports ISO 9001 and other quality standards with certified calibration.

Typical Specifications (Example):

Marking: Laser-engraved identification

Material: Hardened tool steel or carbide

Size Range: 3 mm – 200 mm (custom sizes available)

Tolerance Class: ISO IT6 / IT7 / IT8 / custom

Roundness: <1 μm deviation

Surface Finish: Ra <0.2 μm